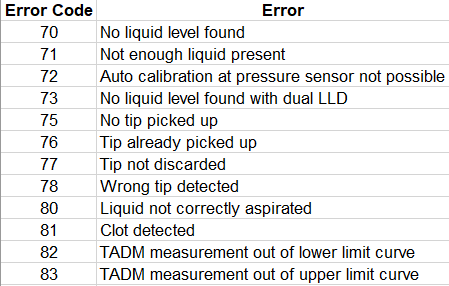

Here’s a list of all the high-level error codes from VENUS 6.0.2:

Main Error Enumeration

ID

Error

Description

0

No error

1

Syntax Error

There is a wrong set of parameters or parameter ranges.

2

Hardware Error

Steps lost on one or more hardware components, or component not initialized or not functioning.

3

Not Executed Error

There was an error in previous part command.

4

Clot Error

Blood clot detected.

5

Barcode Error

Barcode could not be read or is missing.

6

Insufficient Liquid Error

Not enough liquid available.

7

Tip Present Error

A tip has already been picked up.

8

No Tip Error

Tip is missing or not picked up.

9

No Carrier Error

No carrier present for loading.

10

Execution Error

A step or a part of a step could not be processed.

11

Pressure LLD Error

A dispense with pressure liquid level detection is not allowed.

12

Calibrate Error

No capacitive signal detected during carrier calibration procedure.

13

Unload Error

Not possible to unload the carrier due to occupied loading tray position.

14

Pressure LLD Error

Pressure liquid level detection in a consecutive aspiration is not allowed.

15

Parameter Error

Dispense in jet mode with pressure liquid level detection is not allowed.

16

Cover Open Error

Cover not closed or can not be locked.

17

Improper Aspiration Error

Improper Dispense Error

The pressure-based aspiration / dispensation control reported an error ( not enough liquid ).

18

Wash Liquid Error

Waste full or no more wash liquid available.

19

Temperature Error

Incubator temperature out of range.

20

TADM overshot

Overshot of limits during aspirate or dispense.

Note:

On aspirate this error is returned as main error 17.

On dispense this error is returned as main error 4.

21

Labware Error

Labware not available.

22

Labware Gripped Error

Labware already gripped.

23

Labware Lost Error

Labware lost during transport.

24

Illegal target plate position

Cannot place plate, plate was gripped in a wrong direction.

25

Illegal Intervention Error

Cover was opened or a carrier was removed manually.

26

TADM undershot

Undershot of limits during aspirate or dispense.

Note:

On aspirate this error is returned as main error 4.

On dispense this error is returned as main error 17.

27

Position Error

The position is out of range.

28

Unexpected cLLD Error

The cLLD detected a liquid level above start height of liquid level search.

29

Area already occupied

Instrument region already reserved.

30

Impossible to occupy area

A region on the instrument cannot be reserved.

31

Anti drop control error

Anti drop controlling out of tolerance.

32

Decapper error

Decapper lock error while screw / unscrew a cap by twister channels.

33

Decapper handling error

Decapper station error while lock / unlock a cap.

99

Slave Error

Slave error.

100

Wrong Carrier Error

Wrong carrier barcode detected.

101

No Carrier Barcode Error

Carrier barcode could not be read or is missing.

102

Liquid Level Error

Liquid surface not detected.

This error is created from main / slave error 06/70, 06/73 and 06/87.

103

Not Detected Error

Carrier not detected at deck end position.

104

Not Aspirated Error

Dispense volume exceeds the aspirated volume.

This error is created from main / slave error 02/54.

105

Improper Dispensation Error

The dispensed volume is out of tolerance (may only occur for Nano Pipettor Dispense steps).

This error is created from main / slave error 02/52 and 02/54.

106

No Labware Error

The labware to be loaded was not detected by autoload module.

Note:

May only occur on a Reload Carrier step if the labware property ‘MlStarCarPosAreRecognizable’ is set to 1.

107

Unexpected Labware Error

The labware contains unexpected barcode ( may only occur on a Reload Carrier step ).

108

Wrong Labware Error

The labware to be reloaded contains wrong barcode ( may only occur on a Reload Carrier step ).

109

Barcode Mask Error

The barcode read doesn’t match the barcode mask defined.

110

Barcode Not Unique Error

The barcode read is not unique. Previously loaded labware with same barcode was loaded without unique barcode check.

111

Barcode Already Used Error

The barcode read is already loaded as unique barcode ( it’s not possible to load the same barcode twice ).

112

Kit Lot Expired Error

Kit Lot expired.

113

Delimiter Error

Barcode contains character which is used as delimiter in result string.