Are there any alternative options for acoustic plates besides Beckman’s Echo plates? Any insights on other products in the market would be greatly appreciated.

Greiner Echo384PP_781201

Thank you! Have you actually used them and how do they compare? They do not seem to advertise them as echo plates.

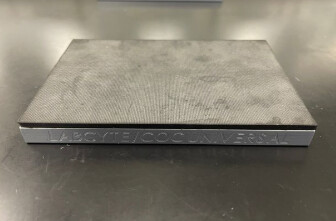

Probably because they can’t. Years ago (and probably still today) Greiner was the OEM for the Echo plates. They just put a “Labcyte” stamp on the 781201 instead of Greiner. Maybe it’s a “Beckman” stamp now? I dunno. Anyways, they had a contract with Labcyte to make all their plates so they couldn’t advertise the same plates for non-compete reasons, but they did sell them if you just asked the sales reps nicely. 15 years ago they had 4 molds for the 781201 plates, but only 2 would work on Echos, pretty sure it was mold 1 and 2. In the bottom left corner of the plate there’s a very small number with the mold number. For use on Echos they also packaged them in anti-static bags instead of normal bags.

We used to buy them directly from Greiner by the pallet, use with confidence.

Looks like it’s these on the Greiner website: https://shop.gbo.com/en/usa/products/bioscience/microplates/storage-plates-for-acoustic-liquid-handling/384-well-polypropylene-storage-plates/781201-906.html

We use the Greiner plates in our labs and they work with the Echo 550, Echo 555, and our Echo 655. From my understanding they are “Echo-certified”. Although for the LDV we still purchase them from Beckman, the “standard” 384 that jnecr, is what we use for “large volume” sources.

I see, we currently use mostly the 384 LDV LP-200 as source plates. I wonder if this is the comparable Greiner for that:

I’d ask a Greiner sales person to be certain. We only ever purchased the higher volume plates I linked above from Greiner. The only other plates we used on our Echos were the diamond well LDV plates with interstitial wells. They were pricey and somewhat difficult to work with, but the low dead volume was great for certain tasks. We purchased directly from Labcyte, although, I’m sure Greiner made those too.

Hi @josequiroz,

I came across this thread and wanted to offer an alternative solution: pressure-based non-contact dispensing. DISPENDIX’s dispense plates couple with their liquid handler to offer a similar liquid handling solution to the Echo, but is faster, cheaper, and more accurate.

Check out these links in case it might be helpful!

![]() More info about our dispense plates: DISPENDIX Source Plates: The Key To Precise Dispensing

More info about our dispense plates: DISPENDIX Source Plates: The Key To Precise Dispensing

![]() More info about the I.DOT Liquid Handler: I.DOT Non Contact Dispenser

More info about the I.DOT Liquid Handler: I.DOT Non Contact Dispenser

Warmly,

Nila

thanks Nilale I am familiar with the i.dot! It is something we may explore in the future.

Hi Jose, did you end up trying those plates? From the product page it seems like they’re the ones

sorry for late reply, we did not. We contiue to use LP200

Hi everyone, we are having issues getting uniform sealing on our Labcyte Echo 384PP plates using the Agilent Plateloc. We have used the specific plate insert, and tried various seal temperatures and seal times, including parameters recommended by Beckman. We have tried two Agilent seal types - PN: 24214-001, Peelable Aluminum RT Seal and PN: 24210-001, Peelable Aluminum.

We are still getting the “hour-glass” shape seal, air bubbles, and it’s highly visible that the left-right sides of the 384PP labware is not properly sealed. Has anyone experienced this and found a solution? A little bit of context: We want to seal these 384PP plates containing DNA parts and store them in the Tundra.

What seal temps and times are you using currently? How well sealed are the parts of the plate that are getting a good seal? Are any wells appearing to be melted/disformed as part of the sealing process.

And you say the specific plate insert. I’m not aware of a specific plate insert, just a combination of plate inserts that can get you to the point where the plate is resting on the bottom of the wells and not on the skirt of the plate. You can actually go higher than that such that the skirt is raised off the PlateLoc nest by several millimeters. The key point being that no part of the plate is resting on the skirt during the seal step.

I have tried the following temps and times. I have not attempted anything higher yet.

- 165C, 3 sec

- 170C, 1.5 sec

- 170C, 2.5 sec

- 170C, 3 sec

- 175C, 2.5 sec

- 175C, 4 sec (recommended by Beckman) - The seal improved marginally compared to the other settings above. The left and right sides of the 384 PP plate are not getting a good seal. You don’t see the “well lines” on the underneath of the peeled seal only the center part of the labware is getting sealed the best. Wells do not appear melted/disformed at this setting.

All the seals we observed from the 170C temps and times showed inconsistent seal performance. We had to use a squeegee tool to push the seal flat down for firm adherence in order to get a uniform seal.

We used this plate insert.

I’m not familiar with that plate insert, but it looks like it says COC Universal on the side? The COC plates are the diamond well LDV plates, not the 384PP plates, perhaps this is your problem? It does also say Universal, so ![]()

The only thing that is important is that the plate is not resting on the skirt during the seal step. If it is, just stack another smaller insert below that one to lift it up.

That insert should be ok and is also suggested by Beckman/Labcyte to use (either LDV or 290 insert). You can reap this up on the current Beckman consumables .pdf for Echo plates.

Were you able to solve that problem? I’m currenlty looking for a new sealer for an automation platform mainly dealing with Echo plates (PP, LDV) but also other plates. According to many other users and Beckman/Labcyte both PP and LDV should seal perfectly fine with either the 290 or LDV insert. Any chance you had some other mechanical defect or is this simply not true and it doesn’t work for you?

Also about the LDV insert: Is the black part on the top of the insert designed so it is less likely to scratch the foil bottom of the Echo plates? Was just wondering because it does look different than the other inserts made out of metal.

@jnecr The black layer on top is rubber, it is elastic but not that thick. I believe it is assumed to help the sealer iron distribute the pressure more evenly in case of plates distort a little upon long term storage or thermo cycling (which every sealing also is).

@GBGenthusiast, PP plates should be fine with 175*C, 2.8+ seconds of sealing in PlateLoc. Do some diagnostic tests, go for higher temperatures short-time, and make sure that the plate surface is actually clean and you are not dealing with some extremely volatile content that may create some significant vapor upon sealing. If you re-seal your PP plates, the top surface gradually melts and closes the wells, which should also lower the requirements for successful sealing significantly as the surface area and smoothness increase. If that is not happening, chances are that your PlateLoc underperforms and needs service.