Hi everyone,

I’ve been trying to Automate the production of standards and QC’s on a STAR for ELISA and am having problems with the QC’s under-recovering and wondered if anybody on here has experience using a Hamilton for ELISA? What kind of mixing step processes you have implemented?

I also wonder if the ‘stock to standards-1’ dilution is very slightly different than the ‘stock to QCs-1’ dilution? I do pre rinse the tip with the stock volume required first, so I hope that’d mean the volumes of stock transferred as similar as possible.

Any suggestions are appreciated,

Thanks,

Ewan

ELISA’s on a Hamilton perform well. We run many at Synthace. Do you think the issues you are facing are with the reagents or the actual protocol?

How much volume are you looking to recover? What total volumes are you dispensing into and aspirating from?

What matrix, mix settings and liquid class parameters are you currently using?

Also what type of dilution is this? A spiking prep or a serial dilution prep?

I’ve had great success with 1 pre-rinse on aspirate into the dispense to the target solution. Then pickup of a new tip and mixing with the new tip.

Then pickup new tip for the next aspirate dispense cycle. It adds time to the prep, but my serial diluted standards are at +/- 3% recovery and the A and P samples prepared were close to +/-5% recovery, likely due to added human error later.

Thank you for the replies so far.

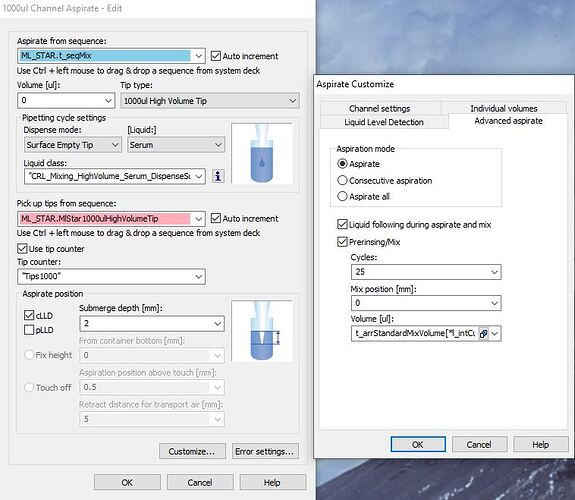

I am doing the spiking and the serial dilutions using the Hamilton. I just use channel 1 to do the ‘stock to Standards 1’ spike and the stock to ‘QC’s 1’ spike as i found more variation if i used two different channels for this step. All the dilutions are done in Serum and i prerinse the tip with the transfer volume, then post rinse the tip with that same volume.

I then have a liquid class just for mixing and it mixes the vial 25 times with the volume originally in the aliquot before the transfer (although i want to change this to 95% of the total volume).

I have had problems when the volumes are around 600 or 700 µL, and better luck with much smaller volumes.

I think it should improve a lot when it is mixing 95% of the total volume, but the exact mixing was a mystery to me until very recently as it is calculated in an array and i’m not too sure about those yet.

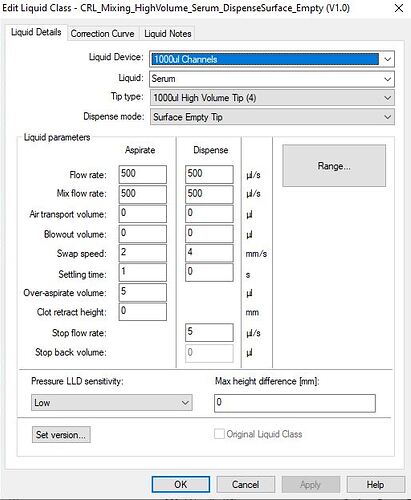

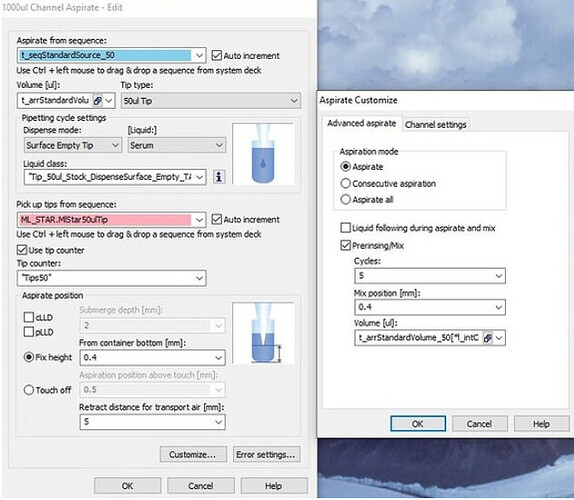

Can you screenshot the Liquid Class Parameters used for the Aspiration and Mixing?

Also Screenshots for the Aspiration settings? the advanced settings portion too?

And Screenshots for the Mixing step settings and advanced settings within that step?

so should be 6 screenshots if I understood correctly.

We ran a DoE for mixing. We did factors like mixing with liquid level following, mixing with an offset from the bottom of the plate, etc so would be interesting to see the screenshots.

I’m curious about you mentioning that you only use channel 1. Hamilton channel arms are pretty robust, so if you see a variation with individual channels, I would suggest contacting a Hamilton engineer to get this checked.

Normally if you see similar behaviour across all the channels then it’s a method issue, but individual channels giving different results is strange so definitely get it checked.

Thanks for your answers, I’ve been really busy today but I’ll get some screen shots tomorrow.

At one point I did test with the curve made by channel one and the QCs by channel two, then a curve by channel 2 and the QCs by channel 1 and all plate on the same plate. The results didn’t match when it was the Curve (Ch One) with QCs (Ch Two), but when it was Curve (Ch One) and Qcs (Ch One) the results matched, and like wise for the ones made by channel 2. This spiking 5 µL of stock into 45 µL of serum.

The machines got serviced a month or two ago and everything was within the tolerances the engineer looks for.

Hi guys,

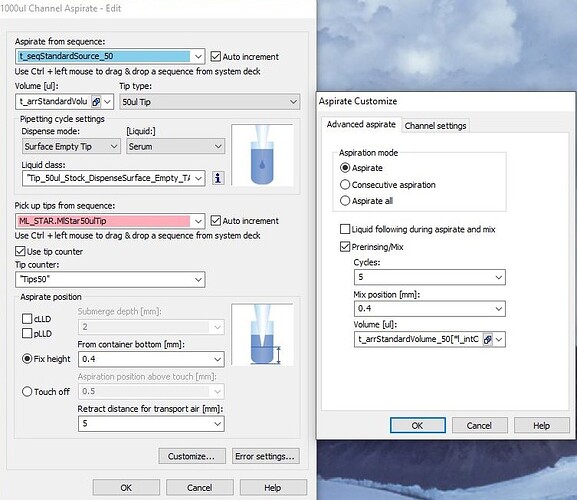

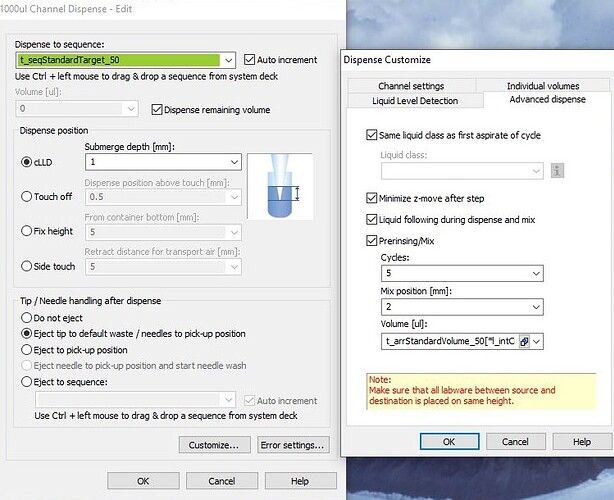

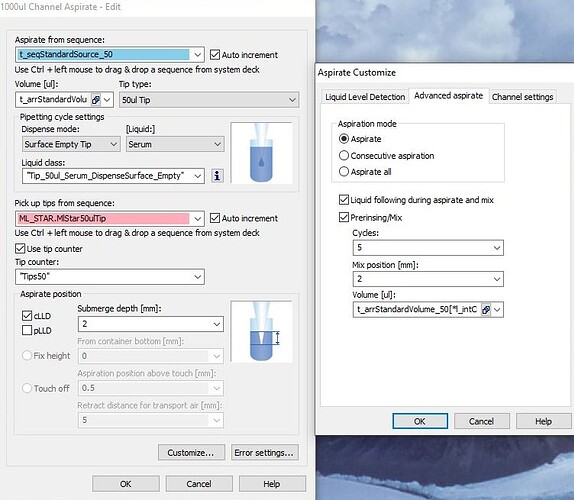

So here are screen shots of my Spike aspirate, spike dispense, serial dilution aspirate, serial dilution dispense, the mixing step and finally the mixing steps liquid class details.

The pre rinse volume is just the volume being transferred and the mixing step is doing the volume in the recieving aliquot, but thats the one i want to change to 95% of the total aliquot volume.

Thanks for any help and advice,

have a good Christmas and New Year everybody.

I just want to point out one issue with the step where you aspirate from a fixed height 0.4mm from the bottom, but for the mix position, you have it also set to 0.4mm. The mix position acts like the submerge depth parameter in that it is a height BELOW the fixed height or a found height from an LLD step. It is not a height from/above the container bottom.

It is in addition to the submerge depth as well so if you have a cLLD step with a submerge depth of 2mm and a Mix position of 3mm, then the mixing will start 5mm below the found height.

In your example, this means that the system is going to 0mm from the bottom which could be problematic if the tip is pinning to the bottom of the tube. You may not be getting a proper mixture on that first step.

Hello,

Given those low volumes, I think it would prove valuable to test ad a fixed height from the bottom of the container without any liquid following or addition mix position.

To echo what Eric was saying Imagine that the when you have mixing enabled in a step that it is almost broken into two actions.

- The instrument goes down to whatever height is specified for the aspiration BEFORE any mix settings are evaluated.

- The instrument will then adjust the height (relative to 1) as defined in the mix position.

So in this case, if you want to mix at the fixed height, I believe, the mix position should be set to 0 with liquid following disabled, and for steps with LLD, set the mix position to Zero as well.

If I Mispoke, someone please correct me and ill edit the post. It’s been a minute since i’ve tested the mixing parameters in detail to solve a similar problem I was having with mixing.

Thank you for pointing this out to me Eric and Brandon. I will change that so the mix position is the same as the fixed height. The aliquot volume being used is so small that the cLLD did not seem to work properly, so I thought a very low fixed height would be a better option for that step.

I’ll give it a run with no mix step and vortex the stock plenty before running the Hamilton, and if this goes okay, i’ll try turning the mix step back on but set at a height of 0.

Thanks again for your suggestions, hint and tips.