Good afternoon everyone,

I just joined the community today but I have been reading through all of the forums and can not thank everyone enough for all of the amazing help!

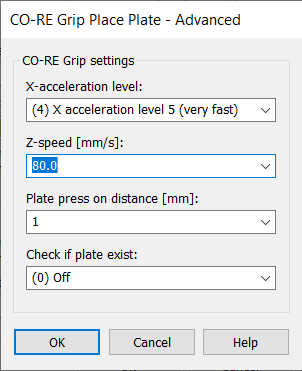

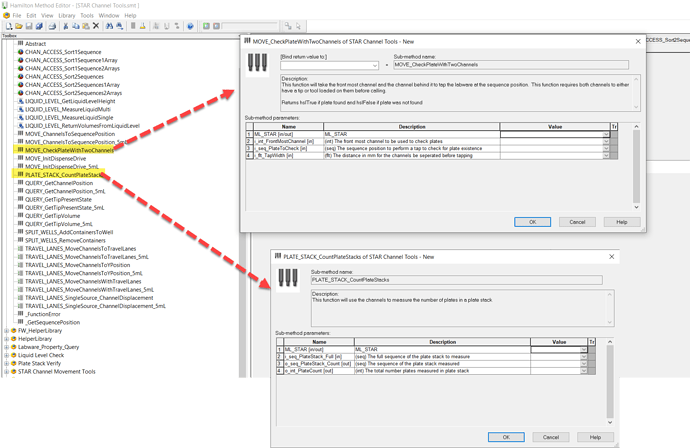

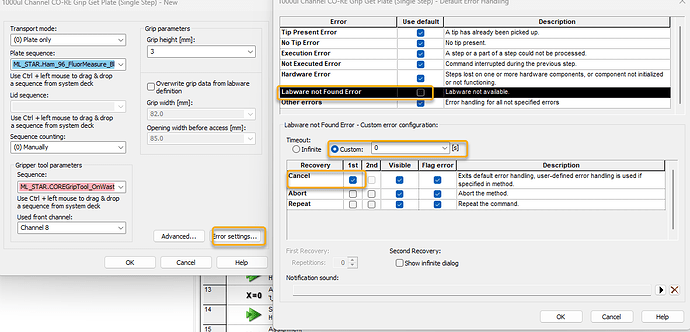

We have an issue on our STARs that I am hoping there is a solution for. Our methods use the CO-RE grippers to move our MTPs from location to location around the deck. To confirm successful movements we implement a plate tap with the CO-RE paddles. Some of the MTPs have been previously sealed with an adhesive film for either cold storage or PCR. The seal material used claims that no residue will be left behind when peeled, but in my experience this is not the case. There have been multiple instances of the CO-RE paddles sticking to residue left over from seal material which caused the MTP plate to flip over off the carrier. As far as I know, successful movement with the CO-RE paddles requires a “plate tap” to check for the plate presence.

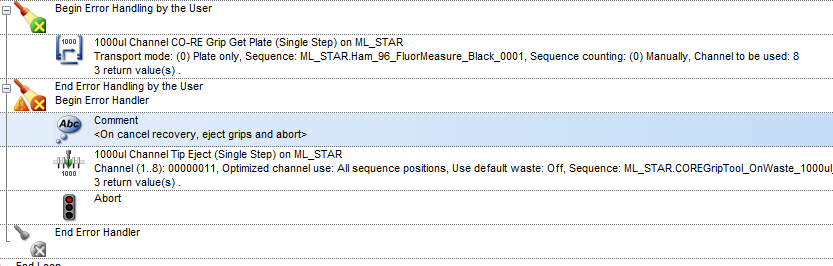

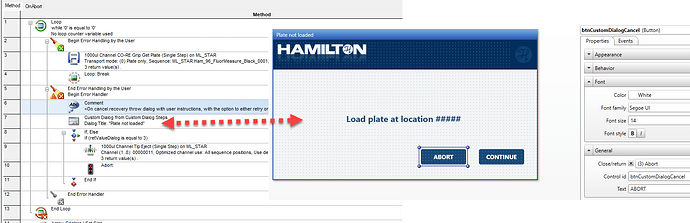

To mitigate risk to the MTP, the “Plate Tap” has been removed on certain plates that may have seal residue on them, but in turn we have lost the ability to know if movements were successful. This leads to transfers to the MTPs destination position but the plate was never moved successfully from its source( ie tabbed carriers were gripping the MTP with enough force where the CO-RE paddles couldn’t pick it up).

Is there a way, with the CO-RE paddles, to confirm if a plate movement was successful without the tap feature? Any guidance on this issue is so greatly appreciated. Thank you so much everyone and have a wonderful weekend!