Hi @serg

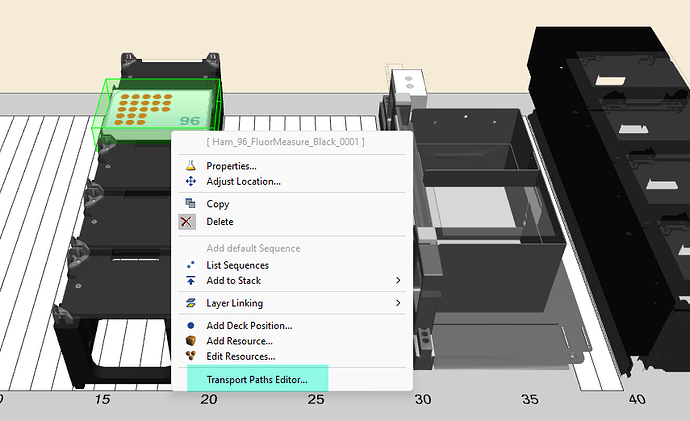

To access the paths editor UI simply:

Open your deck layout of interest

Right click on any .rck (plate) labware on the deck, but I recommend right clicking on the labware you intend to use as a source plate for the IPG to load for teaching

Select ‘Transport paths editor’ from the context menu

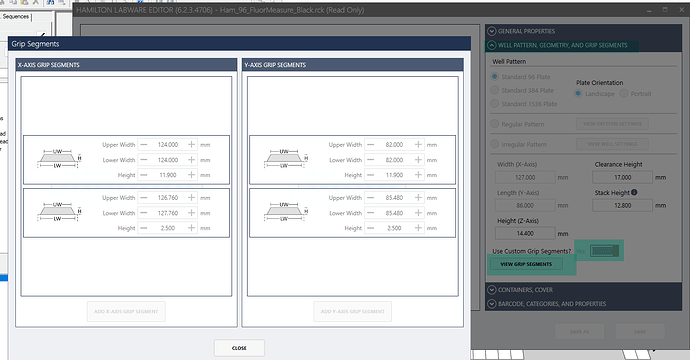

For the plate used during teaching, ensure that the labware definition has grip segments defined for the full height of the labware. This is required for IPG path teaching to function.

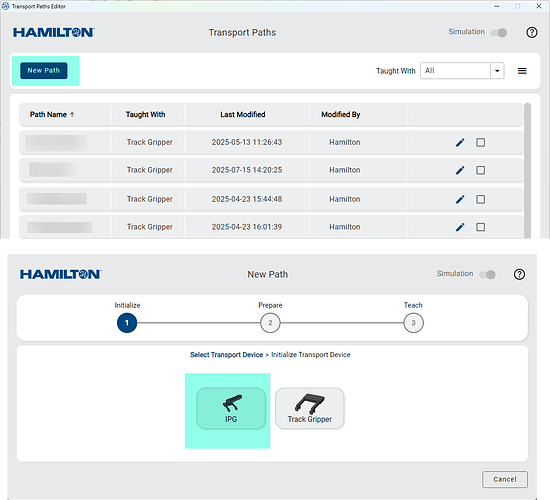

Once the teaching client UI is launched, toggle simulation off and then select ‘New Path’ followed by ‘IPG’

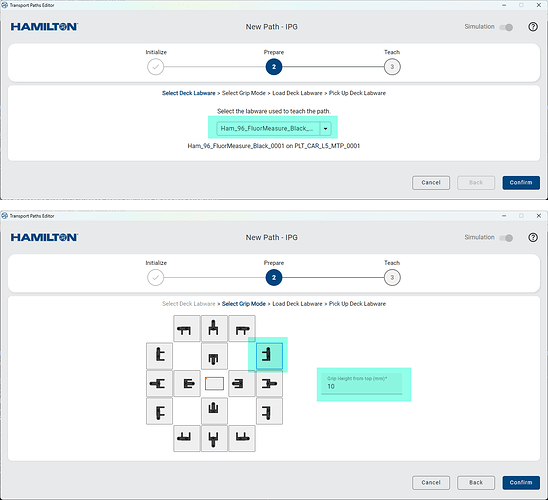

If you right clicked the labware you intend to use as the source plate for teaching, the corresponding labware Id will auto populate in the selection drop down. Select your source teaching labware, then the grip direction you want the plate to be accessed by and finally enter the grip height you want to use (relative to the top of the wells/container of the plate/labware in regards to the deck layout coordinates).

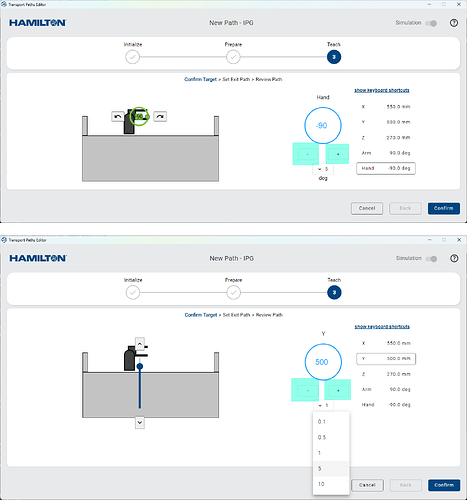

At that point just follow the remaining prompts to have the IPG load the labware and commence the teaching process. Select the axis you want to move, then the movement increment from the dropdown (mm for XYY, degrees for arm and hand). The ‘+’ and '- ’ buttons can be used to jog the axis relative to its current position by the selected increment. + being positive direction and - being negative direction. For arm and wrist, + is counterclockwise and - is clockwise.

For X, Y and Z you can also use the slider for large movements but please exercise caution and judgement for suck movements.

Keep jogging axes until you get your plate in its desired position/handoff. It does not matter how you get there or how many movements, the UI does not track these for path definition purposes. Once the plate is in its desired handoff, select ‘Confirm’.

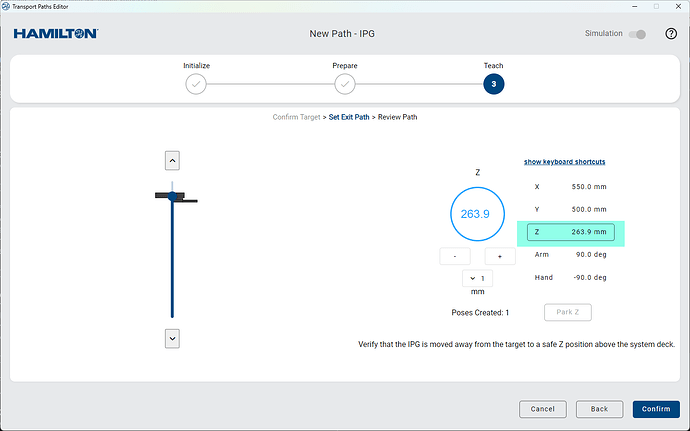

Once you are at this step, this is when path definition actually begins. Select the axis you want to move at this part of the exit path, then jog each movement methodically per how you want the IPG to access and depart from this location (you are teaching the departure sequence, approach will be done in reverse of the path poses).

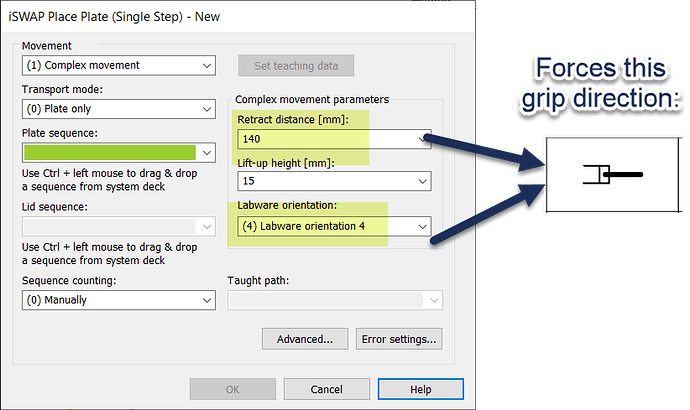

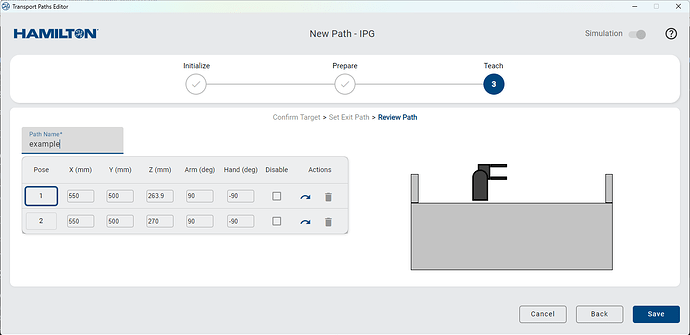

Many axis menus will have the option to park to its home. These are convenient when applicable. Path teaching will be complete once IPG Z is at traverse/home. No other axes will be required to be home or even orthogonal. At this point the UI will display the path poses which can be tweaked/edited manually if necessary. Name and save your path and you can then call it using IPG ‘get plate’ and ‘place plate’ method editor steps when toggled to custom path mode (note the example below is just to show what the UI menu looks like at this point). Your path will likely have more than 2 poses (there is no practical upper limit I am aware of). Each jogging movement you define during the ‘Set Exit Path’ portion will define a pose of the path

I recommend playing around with the UI in simulation a bit to get comfortable.

Thanks and let me know if you have questions.

-Nick