Hi all,

I was wondering if anyone else pipettes with a 96Head to a 24w plate. The best way I can find to do this right now is to trick the software and move virtually a 96w plate to where my 24w plate actually is.

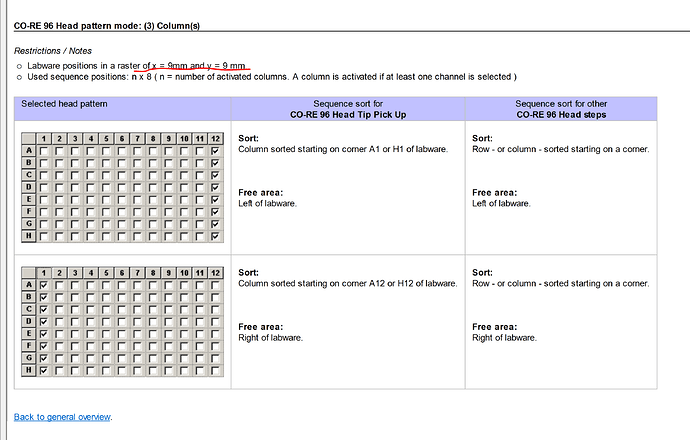

Reading the " CO-RE 96 Head Pattern mode limitations" all modes seem to require a 9x9mm raster? Is there a better hack to get around this?

Hi, @cwehrhan,

The advanced training states the following about this topic:

Pipetting with a 96-Channel Head for a 24-Well Plate

-

General Requirements for 96-Channel to 24-Well Pipetting

• Overlapping Labware: Ensure overlapping labware to align 96 sequence positions to the 24-well plate.

• Raster Alignment: Use an 18mm raster for the 24-well plate to ensure optimal tip alignment.

• Test Alignment: Verify alignment by using the 96-channel head (96MPH) and the desired tip pattern for teaching positions.

• Tracking Limitations: Sample tracking may not accurately detect 24-well plate positions, and volume calculations/following will be unreliable.

• Interaction with “Fake” 96-Well Labware: The 96MPH steps should interact with a virtual or “fake” 96-well labware overlay on the 24-well plate to maintain sequence conditions.

-

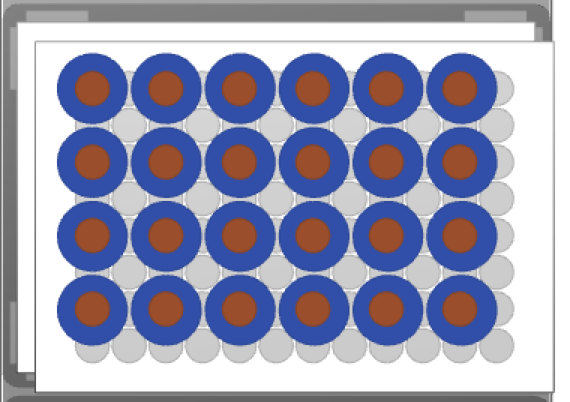

Tip-to-Well Ratios and Applications: 4:1 or 2:1 Tips per Well (Overlapping with Snapped Labware)

• Tip Configuration: Use overlapping labware with either four or two tips per well.

• Volume Capacity: Enables dispensing up to 4ml per well.

• Well Considerations:

-

Round Wells: Mind the dispense height; tips may fit, but the channel barrels might not fully clear the well.

-

Square/Flat Bottom Wells: Provides better access to the bottom of the well.

• Alternating Tips (2:1): Use either row-wise or column-wise alternation for washing applications.

- Applications: Ideal for washing plates, e.g., BVS or MPE2.

-

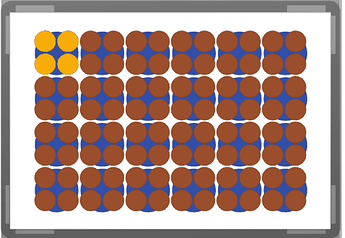

Tip-to-Well Ratios and Applications: 1:1 Tip-to-Well Ratio (Adjusted with Aligned Labware)

• Labware Positioning: Adjust the 96-well plate location so that A1 of both the 24-well and 96-well plates align.

• Reliable Aspirate/Dispense: Enables bottom aspirate or dispense positions, though volume following and speed calculations may be inaccurate.

• Channel Pattern Requirement: Must use a continuous channel pattern; alternate tips through physical arrangement if needed.

Ah yeah this is pretty much what I’m doing except with some tool to line up the A1 of both plates automatically. Was wondering if there was a better way since as they noted:

“volume following and speed calculations may be inaccurate”

1 Like