Hi all!

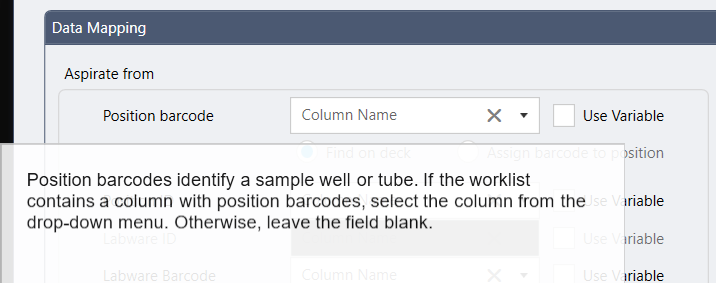

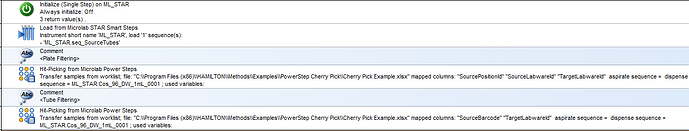

I’ve been playing around with Venus’ Hitpick Powerstep and I noticed this little blurb when setting up worklist handling.

If I understand this correctly, this could allow for a unified worklist that contains barcodes read from tubes and plates, and transfer the contents between tubes and plates quite easily if I use position barcodes. Based off of my current understanding of labware barcodes and position IDs, this sort of mixed-level transfer is fairly difficult as plate barcodes require a additional position IDs while tube barcodes don’t accept position IDs, as they are a position barcode rather than a rack barcode.

However, I have no idea what format Venus is expecting a well position barcode to be. Is it something like platebarcode_A01 or platebarcode_001? Or is this something exclusive to plates like matrix plates, where each well is truly uniquely barcoded?

I’m dreaming of a “universal” hitpick method that allows our users to use a single worklist template set up most everything, and let autoloading and a few dialogs figure out the rest. Hopefully someone can shed some light on how to format a well position barcode/how to generate them and I can make this happen!

Thanks,

Forrest

Hello,

While my understanding of the hitpicking powerstep is very limited, the position barcode refers to the actual barcode of a given position as a string value. So from your example above, the entire strings “platebarcode_A01” and “platebarcode_001” are in their entirety barcodes with no reference to their actual position on a given rack. The labware barcode just below that section in the powersteps is the actual barcode of the rack or sample carrier itself.

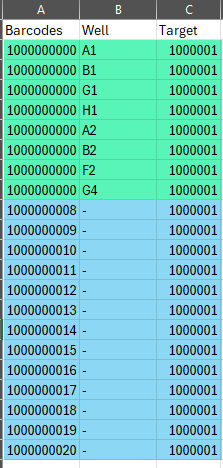

Note that whether a plate is a matrix rack or a regular rack, a user and Venus can assign barcodes to both the rack and each position as they so choose. Those barcodes are used for sample tracking purposes and can be the actual barcodes found on the physical labware that you can see and read, or anything else (you could assign 1 rack barcode and 96 position barcodes to a microtiter plate even if it doesn’t have visible barcodes on it).

Positions like A1, B1, C1 or 1, 2, 3 (for sample carriers) are string values found in the actual labware definition. These are called position IDs in the same section of the hitpicking powerstep.

The other thing about the hitpicking powerstep is that the user has a choice for “find on deck” or “assign barcode to position”. Prior to getting to the hitpicking step in your method, if you already assigned barcodes to racks, carriers, and their respective individual positions, then you can use the “find on deck” option to search the deck for the barcodes you specified in your worklist. This will be independent of the position ID requirements. Alternatively, if you have not assigned barcodes when getting to the hitpicking step in your method, then the only option is to “assign barcode to position” meaning that the position ID specified in the worklist at the specified labware will be assigned the position barcode during (or after) the hitpicking process.

I hope this helps!

3 Likes

Ok, so if I understand correctly, autoload will read and attach a rack barcode to a plate, but no position barcode is generated. Position barcodes will have to be generated in a separate step and attached to the wells in the plate prior to the hitpick if I want to use the “find on deck” functionality with both plates and tubes in the same step utilizing a position barcodes.

This is specifically to enable autoloading plates and tubes and to use “find on deck” in a hitpick powerstep. Does this idea of making and assigning computed position barcodes for plates (concatenating the scanned barcode and well positionID) and using the autoload position barcodes for tubes make the most sense for this purpose? Is there a simpler way to do this?

Best,

Forrest

Hi @MelloMood ,

It really depends on what you are looking to accomplish. If you are always transferring from set positions, then a simple sequence input / output should take care of your situation.

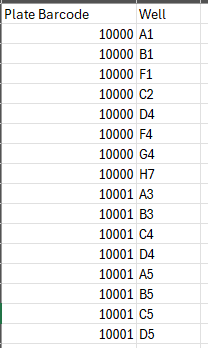

If you want the ability to find the plate and transfer from/to wherever it is on the deck, then that is where the plate barcode option will shine. This will find the plate on the deck, even after the plate has been transported. You would just need to include a second column that includes the wells that you want to transfer from/to.

Consider barcodes within PowerSteps as dynamic Labware ID/Position ID combo for container barcodes and dynamic Labware ID for plate barcodes.

You can still work with a universal worklist, the users just have to know what well they want to pick from in particular plate barcodes.

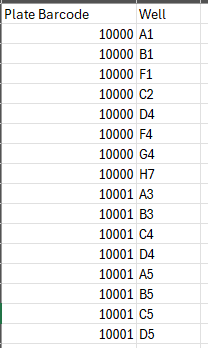

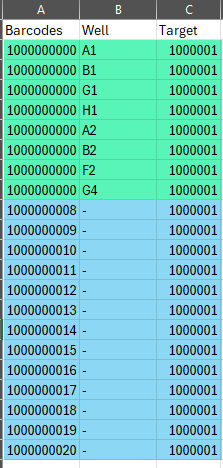

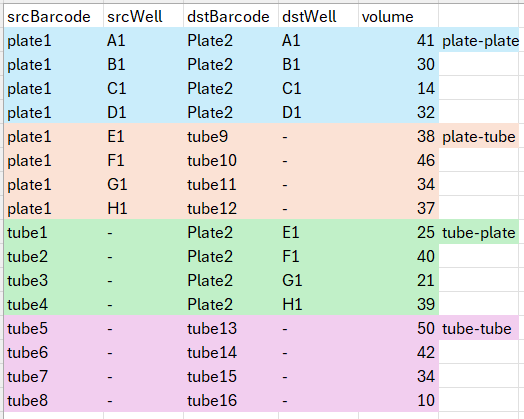

For example, the list below could be used to cherry pick from 2 plates and then dispensed in order to a target plate.

If the users want to dictate the target plate, you can add a third column that dictates a target plate barcode. If a target well is not specified, then it will progress the sequence in order of the plate sequence on the deck.

2 Likes

Hi @BrandonBare_Hamilton,

I think there’s a miscommunication happening! I current use the plate barcode option and use the Labware ID/Position ID for worklists, and it works great for plate only workflows. I have a couple of workflows where hitpicking from barcoded tubes held in sample racks sample carriers into plates would be very useful. One example is spiking in controls, which have been aliquoted in tubes, into assay plates.

I want the ability to find plate(s) AND/OR tube(s), and transfer to/from wherever they are on the deck.

Hi @MelloMood ,

That is certainly possible, but it will require additional hardware to be able to accomplish. Scanning tubes in sample tube carriers achieves this using the autoload. When the barcode is scanned, it is applied to the tube (well position).

However, the autoload can only scan the side of a tube rack that fits within a SBS position on a plate carrier. To be able to scan the tubes within a tube rack, you would need something like the easyCode carrier or LabElite that can take a picture of the bottom of the tube rack to be decoded. Once they are decoded, they can be applied to the tube rack labware and then the PowerStep will work as you want it.

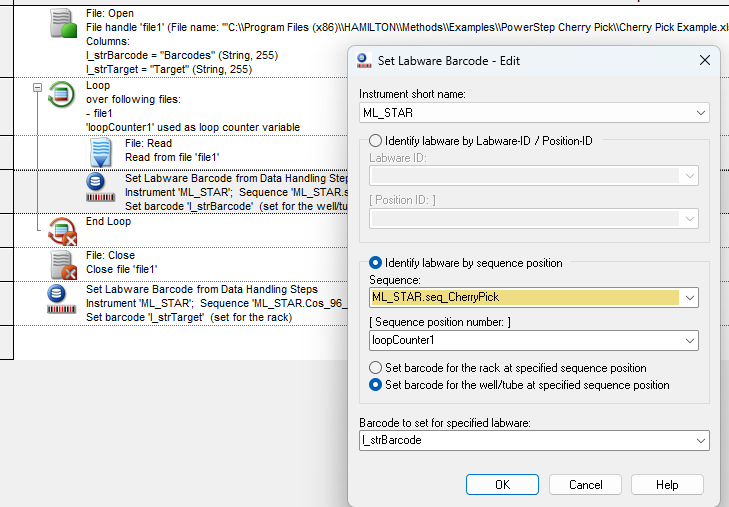

If you do not have the ability to scan the tube rack barcodes, you have to tell VENUS where the tubes are located within the tube rack. This can be done by reading through the worklist and setting the barcodes with the Set Labware Barcode function within Data Handling Steps. You can also set barcodes to positions using this same technique for tubes that are always in the same location.

Unless the barcode is specified to the sample tracking, VENUS will not know where it is on the deck.

Sorry, further clarification due to incorrect verbiage. I meant sample carrier, not sample rack. I want to scan tubes and plates using the autoload using the respective carriers that allow for scanning of the tubes or plates, but then hitpick between the scanned tube barcodes and the scanned plates/specified wells in given plates.

Hi @MelloMood ,

Ok thank you for the added clarification. This is something you can try to accomplish this goal.

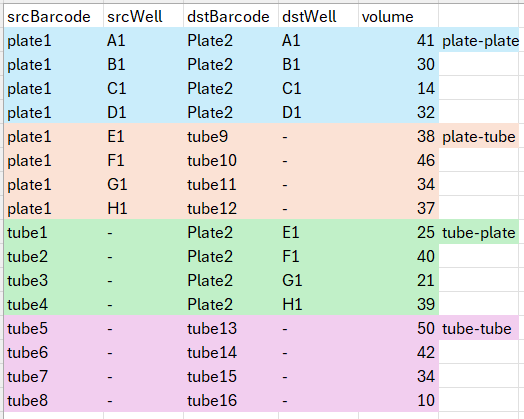

The green rows would correspond to a plate where you specify the plate barcode and well to aspirate from. The blue rows correspond to tube barcodes where only a barcode is specified (well is marked as a - ).

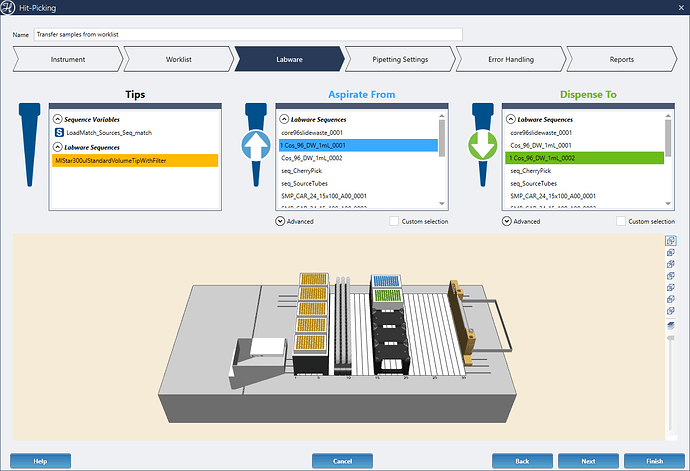

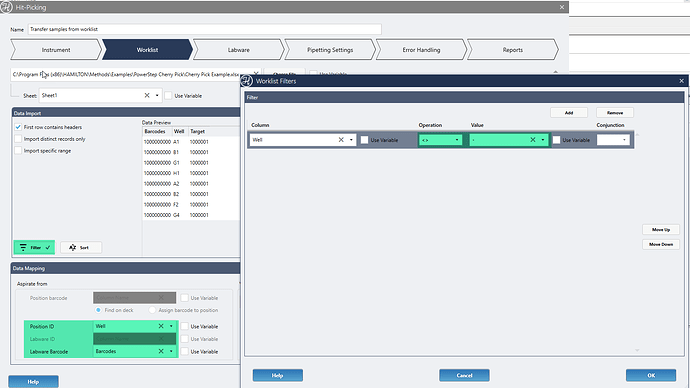

Within the PowerStep, you can add filters. See below for Plate based filtering:

Notice that the Position ID and Labware Barcode are marked in the Data Mapping.

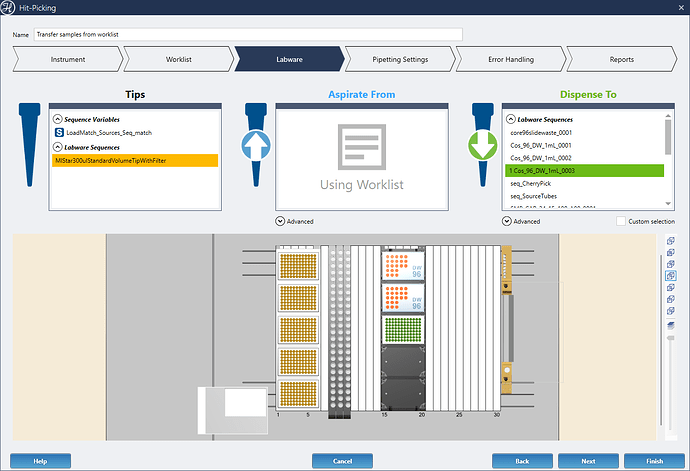

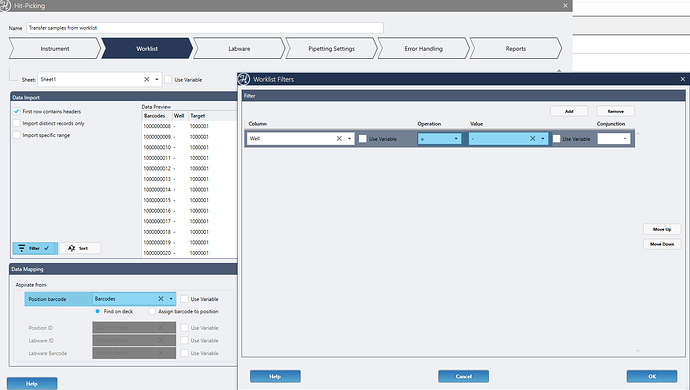

For Tube based filtering see below:

For these positions only the Position Barcode is mapped.

This does require two commands to be called, but only one worklist is needed. If the filter returns 0 rows, the transfer will be skipped.

Hi @BrandonBare_Hamilton ,

OK! My understanding is that the filtering you suggest above will let me select plates OR tubes as the source from a worklist, and I would have to do the same sort of filtering on the destination barcodes as well. What I think is being suggested is to filter the worklist depending on if plates or tubes are the source/destination, and run a seperate hitpick command for each combo?

Hi @MelloMood ,

Correct in this scenario you would run your Cherry Pick steps four times. One for each scenario that you specified.

1 Like