Hey all,

Situation: Core-II stop disk works fine with core-ii 1000 uL and core -ii 300 filtered tips. 1000 uL channels.

However, core-ii slim tips would be better for the method I’m developing.

Problem: We only have the “normal” carrier. I don’t remember all specifics and am not in the lab, but the tips fit and there are no errors in simulation mode, tip pickup and when pipetting.

Nevertheless, when the tips are picked up one can see that the channels apply way more pressure on the core-ii 300 uL slim tips.

This goes so far that one can hear a sound which sounds like something is about to break. Luckily everything goes fine and I have done this about 100 times now while testing.

Is this normal?

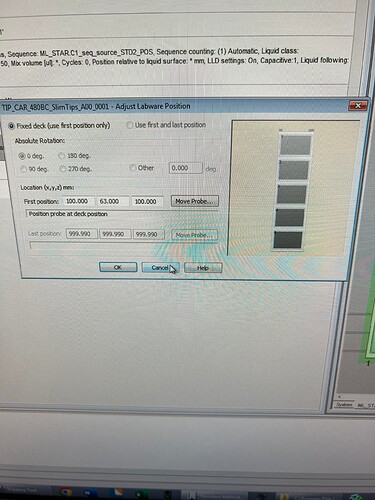

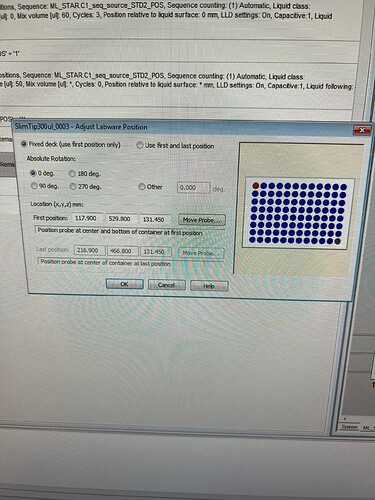

I did measurements on the positioning and checked the positions of the lab ware (identical position (x, y, z) of slim tips on normal carrier & slim tip carrier, as well as identical position of slim tip carrier and normal carrier) and was not able to detect anything suspicious.

Does anyone have advice? Scared of breaking stuff ![]()