Definitely utilize the Hamilton Liquid Handling Guidebook - it is a great resource to have. Other than that, I’d recommend starting with the basics first. LC in FluentControl can be massive rabbit holes and you don’t often need to level of control that microscript offers for every liquid type. Start with simple things like aspiration/disp speeds, delays, retract speeds, and touch-offs.

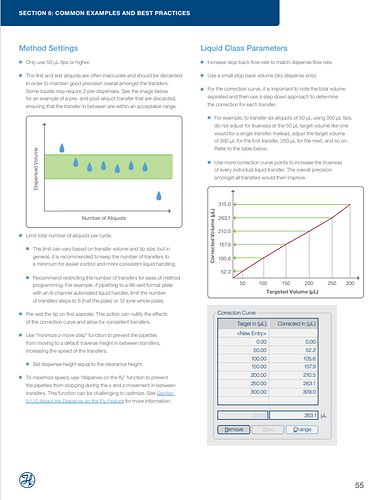

A validation approach that has been working well for me is to first define your needs, translate that into single vs multi, tip sizes, and volume ranges, then fine-tune your LC starting with highest volume aliquots to visually check for droplet formation and clean/even delivery. Move to gravimetric testing with replicates across the whole range of volumes to fine-tune your calibration (accuracyadjustment()).

There are some hidden functions in fluentcontrol that will be useful - you’ll want to use the help manual and navigate to operands and functions to better understand what tools you have available. Similarly, there are some hidden attributes such as X_TIP_TOUCH and Z_LIQUID, Z_BOTTOM, etc that are useful. It’s been a minute since I’ve used FC but I be sure to look at default LC for clues on what tools are available.

@J_Evans submitted a great rundown on LC optimization in an earlier post. The whole thread is worth a read. https://forums.pylabrobot.org/t/liquid-class-optimization/135/24?u=evwolfson

EDIT: Quick update for my own $0.02 on your questions:

(1) For a multi dispense LC: would I want a trailing air gap? Since it’s repeat dispensing, wouldn’t this mean the first dispense would have less volume than the rest since it would include the TAG? Or is the ‘TAG’ checkbox in the dispense step meant to deal with this?

Use TAG if droplets are seen, but be aware that they add to your tip volume capacity and can affect how many aliquots can be transported at once. The TAG is aspirated after the entire liquid column, including multiple aliquots. For multidispense, your excess volume will be handled with conditioning and overage to (respectively) provide excess volume for 1st and last dispenses.

(2) if a multi dispense (ie - Reagent distribution function) has observable droplets on the tips - how would I fix this? I am using the ethanol free multi LC as a starting point for my internal standard solution in methanol.

Good starting point - play with retract speed to find the balance between limiting vapor pressure buildup and the effect of quick movement on liquid equilibrium within the tip. I often variablize delay and retract speed within microscript to make changes easier. I’d also recommend a significant pre-wet and delay to equilibrate temp and pressure. A single dispense or significant overage may be required for this liquid.

(3) Would it be better to do multiple aspirate/dispense steps (ie like using a variable pipetting loop) rather than a reagent distribution for more volatile solvents like methanol?

Probably, yeah. In general variable pipetting loop will give you better control, but once you find a solution you can fine-tune microscript and utilize reagent distribute smart-steps for implementation. A trick I often used was to create an LC called “Do_Nothing” that did literally nothing and set that as my LC for dispensing excess to waste which reduced loss between aliquots when using reagent distribution smart commands - might be useful if you need to use individual transfers rather than multi.

As a last comment - ask Tecan Helpdesk. They may have some engineers that have run into this problem and can provide LC for you - which may work but at worst case would provide a template to learn from.