I’m new to the Tecan Fluent Control software and have been working on optimizing liquid classes for our DNA extraction protocol. I’ve been having issues with our beads/binding buffer master mix. Since the beads settle out of solution easily, I have a Mix step before the Reagent Distribution. The master mix is being mixed in a reagent trough using the 8 channel Air FCA and then distributed to wells of a 96 deep well plate.

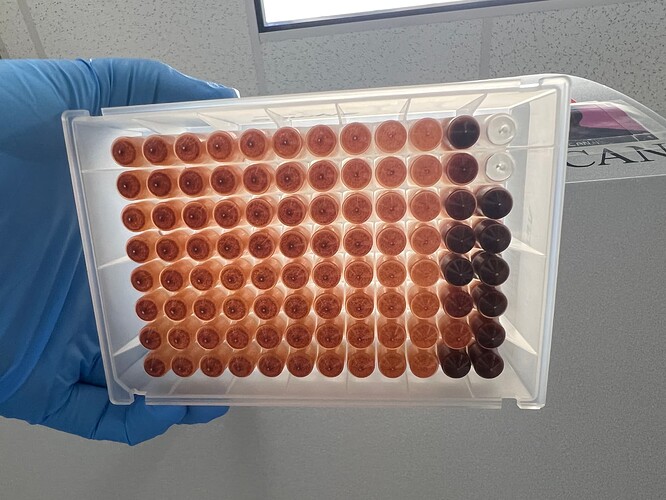

The mixing step is only mixing at the surface of the liquid, so many beads are still settled at the bottom of the trough. This is causing an uneven distribution of beads across our 96 well plate during the reagent distribution. I don’t see an option in the script to adjust what z-position the tips are when mixing, so I’ve been looking into the submerge depth for the liquid class. Is there a formula that would allow me the tips to mix at z-max? I don’t want to assign a numerical value to the submerge depth since we work with varying numbers of samples and the total volume in the trough can range from 10mL - 67mL. If this is not possible, are there other variables I should look into? Thank you!!

The Macherey-Nagel NucleoMag Vet Kit

If you’re using the SMART commands, you cannot directly integrate the mix. You will have to create a custom mix step in the LC which gives you a tremendous amount of power but is bespoke.

There’s guidance posted around the forum that is a great starting point. Alternatively you can create a Variable Pipetting Loop with Mix directly integrated.

2 Likes

Make sure your beads are room temp - they can be viscous at cold temps.

With Tecan, mixing at low/high z_dispense is key as the Tecan syringes form more of a jet then a large mix-inducing movement. You will need to cycle between aspirate low/dispense high, and about 10-15 cycles in addition to periodic mixes during the dispense cycle depending on your settling time, but every 3-4 dispenses is typically good.

As for dispense height, you’ll want to consult the help manual (F1) and you can find an entire section on functions & operands that can be used within a microscript. The key for variable volume will be to detect liquid, then set your mix height limited by z_Max and z_Liquid. The software will track liquid level and adjust z_liquid accordingly, but you can always double check with LLD and math. As this is done in microscript, it is friendly to partial-plate setups as you described.

Similarly to what @luisvillaautomata mentioned, you will need to create variable pipetting loops to incorporate periodic mixing at the source trough. Mixing at trough will require a calculation to ensure you are not overaspirating. Something like Max((Reservoir vol/ 10) , (75% tip vol)) would be adequate to prevent errors or overaspiration.

Loop(1-96 samples, variablized)

If loop_cycle mod 3 = 0

mix

Aspirate/dispense into dest wells

Next

Variable pipetting loop will take care of sample number and reagent conservation. Your biggest issue will become accurate delivery of same-concentration bead mixture.

2 Likes

based on mixing a reservoir with 10-67 mL in it, your best approach might be a loop where you aspirate from bottom, dispense near surface of liquid - repeat this 2-3 times, then shift the tips to aspirate from near the surface, and dispense just above the bottom - again, repeat this with fast liquid dispense

repeat all the above 2-3 times depending on the trough’s volume,

i’ve been successful with the above approach using an array of “AspHeightOffset” to cycle tip from 2 mm above Zmax, to 12 mm above Zmax etc - and also a “DispHeightOffset” to change tip height during dispense

micro-scripting has huge flexibility - it just isn’t well documented how flexible or the best use cases for your needs

2 Likes

Also want to add that a 3.0 mm shaker is clutch for mixing tough beads in a plate.

That specific orbital will keep your beads very happy.

2 Likes