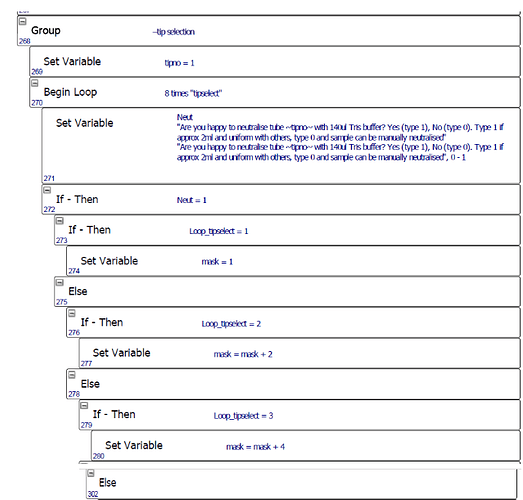

I want to use a selection of tips that may vary run to run in Fluent which I have done with tipmask on EVO. Is this possible? e.g. ask user individually yes/no if you want to use each tip and works out the unique tip mask number to only use that combination of tips.

2 Likes

tip masking is available in FluentControl,

there is even a “power of” function (2^7) which makes the logic easier to handle if you want to use sequential tips

for “random tip selection”, building a tip array would be easier to manage the step by step switching of tips on/off

i’ve had great success with random tip selections, optimized disposable tip types, optimized liquid class selections for pipetting of a wide range of volumes & liquid viscosities in parallel - with high degrees of accuracy and precision

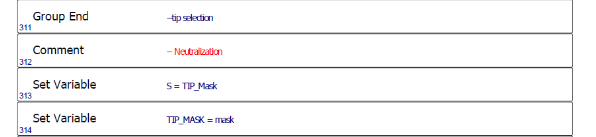

Thanks very much. I’m just beginning to look at the inbuilt variables in Fluent Control and don’t remember specifically seeing tip mask on the list. If you don’t mind can you share how it would look to set tip mask in Fluent Control (Variables seem more formula based vs. EVO), I’m guessimg using the set variable command?

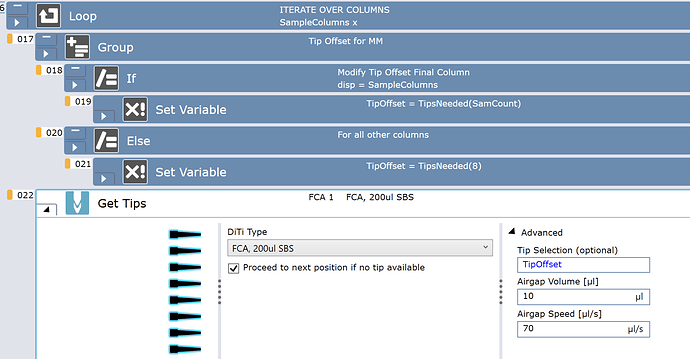

Tip Selection under Advanced for FCA command’s

And as Daniel alluded to, TipsNeeded() is the function for sequential tip use. It’s super useful.

2 Likes

It might not be sequential tips though e.g. if you wanted to do 1,2,5,7 or is the 8 in tips needed the tipmask unique number? I will play tomorrow.

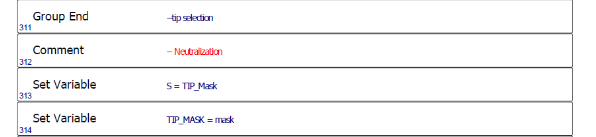

Definitely in which case you’re going to want to calculate that number

channel 1 = 1

channel 2 = 2

channel 3 = 4

channel 4 = 8

channel 5 = 16

channel 6 = 32

channel 7 = 64

channel 8 = 128

so if I wanted to only use channels 1,2,7,8 then it would 1 + 2 + 64 +128 = 195 and I would enter 195 into TipSelection to just pick up those tips in the example above.

Also make sure all 8 tips are selected and highlighted blue as seen in the picture above.

Finally, have fun.

3 Likes

@luisvillaautomata Thank you for the clear explanation! This really helped me out in a an Evo situation where I needed to control aspiration from a single tube (requiring 8 aspiration steps for each individual channel), and had a variable sample number. I was able to make a quick lookup table and import the right TipMask based on my Sample Number. Appreciate you taking the time to lay this out!

1 Like

!!! Love it!!!

It’s also super powerful with arrays and when paired with the well offset aspirate/dispense options. I’ve had entire blocks of legacy code reduced to a single loop statement with asp/disp.

It also allows you to be more flexible with your subroutines so you can (in theory) build less of them.

1 Like

I agree! I actually did use the Well Offset Variable too, as I woudl have variable destination locations depending on the number of samples being processed, and the loop logic built into aspirate/dispense couldn’t handle what I wanted to do with my multiple nested loops.

It took something that I thought for sure i would need to use a Worklist for (which would require writing some VBA to make the work-list) into something that could be done just through Evo. Thanks again!