Hello everyone! I want to add a plate tap post rack placement for the Autolys racks. After looking into the rack definition and container definitions I realized that the .ctr for the Autolys tubes are just the outer tube. The inner tube and cap are not accounted for. This makes for a pretty violent plate tap and z step loss. considering how the “top of labware” is calculated based off the container depth and where it sits, is there anyway to add something in the labware properties (for example the heights for the cap distance and lift and lock for robotic channels) but have this be applicable for any of the core grip movements? Though the ctrs loaded are at this height when being transported there is a +10mm on top of the container. Any ideas and guidance would be greatly appreciated! Thank you so much!

Oh, that sounds hard to get around.

Why are you using check plate feature on the Autolys? To push/seat the rack with plate check or confirm that the rack movement was performed correctly? Is one side of the Autolys rack weighed with tubes but not the other side?

@bowlineknot you hit the nail on the head. That is definitely one of the instances where the plate tap would be great to have. I’ve tried a bunch of different things. There’s always a workaround in Venus but I’m stuck with this one. Is there something funky I could do with a cover definition, it was a thought I had. But at the same time I’m trying to simplify the code in our methods. I even thought of maybe a ctr swap before and after each movement step, but that could get a little messy too. Thank you so much @bowlineknot please let me know if you think of anything!

I have two ideas that don’t involve using the plate check option.

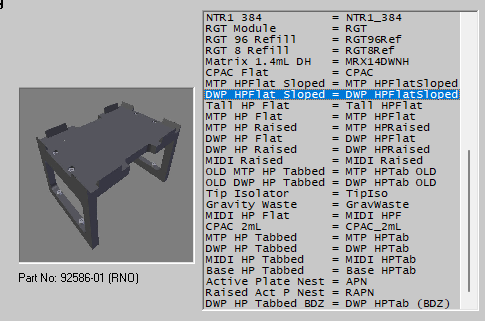

If you can use another carrier, one MFX carrier with sloped metal tabs position. That might help with the rack sliding into place correctly without using the plate check. I’m assuming you have the plastic tabbed plate positions.

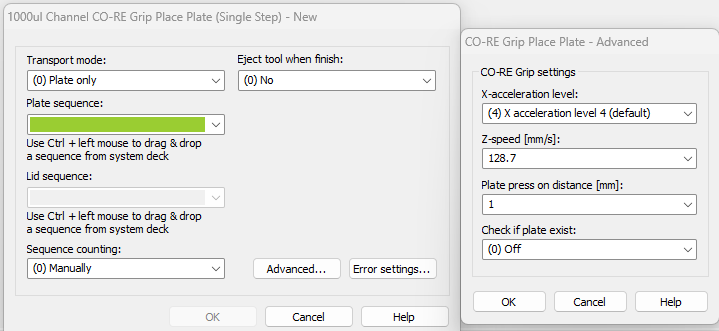

Another option is to increase the plate press on distance to push the rack into the deck position during the plate movements. Default is 1mm.

@bowlineknot thank you so so much!

I am going to try an increase in the plate press next, something that I didn’t try because of the “plate tap” tunnel vision.

It is funny that you mention the slopped plate pedestal. That was one of my thoughts as well to try and mitigate a movement error from retrieving the balance rack out of the SBS centrifuge. Another issue we have seen a lot is when the centrifuge moves the rotor so the CO-RE paddles can get the rack, the “play” in the x shifts the labware right. When the CO-RE paddles grip the rack, its gripped more left causing placement errors. Which ultimately could lead to rack cancelations. The sloped plate pedestal for this particular issue did not solve that unfortunately. @bowlineknot Is this something you have seen? This has been haunting me. Is there some functionality in the the CO-RE transport library/ centrifuge teaching methods that mitigate this off center rack transport?

It’s a very common issue to see with plate movements in general. When I’m trying to dial in plate movements I have a test method that just loops over all the plate movements from start to finish. I use my phone to record movements and adjust the teach points on the deck layout based on what I see/record.

For the play you see in the centrifuge, I would teach the centrifuge plate position to where the rack would “rest”, in your case the right if possible. If not you can use one of the virtual labware libraries (HSLLabwrAccess - Labware Access Library) to shift your labware on the position to the right before pickup.