Hey everyone -

Im trying to build a method that utilizes Barcode IDs to build source & target sequences, but I cant figure out how to use realistic ID’s instead of the default “Barcode01” IDs that are automatically generated in simulation mode. Is there a best practice for this? Im using the easyBlood autoload library for sample loading and scanning, if that helps. Thanks y’all!

just have it ask for a barcode input file when it detects the Run Control is in simulation mode.

While the default barcode assignment for racks and positions during simulated ML_STAR load steps cannot be overridden within the step, you can absolutely assign desired custom barcode data by overwriting the default barcode values after the step.

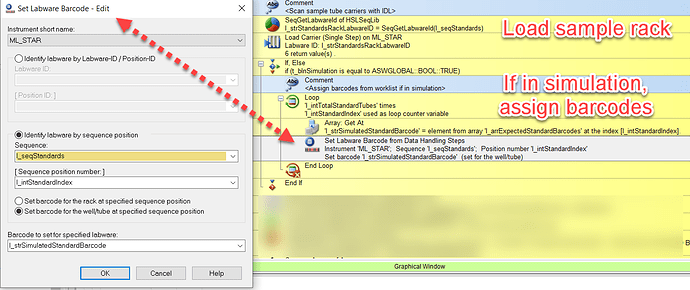

For simulated runs, I typically add in a block of code right after a load step to assign simulated barcode data to the racks and positions of interest. These barcodes are typically read in from a file earlier on in the run and stored in an array. See the example code below:

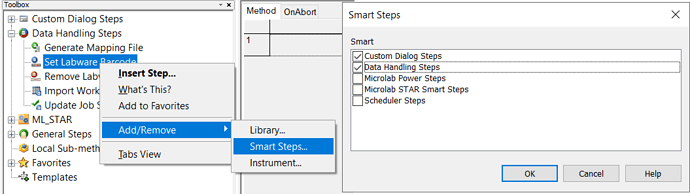

There are a few different functions that facilitate assignment of barcode data to racks and containers, but I recommend using the ‘Set Labware Barcode’ step of the data handling steps shown above. These steps can be added to your method editor toolbox similar to smart steps.

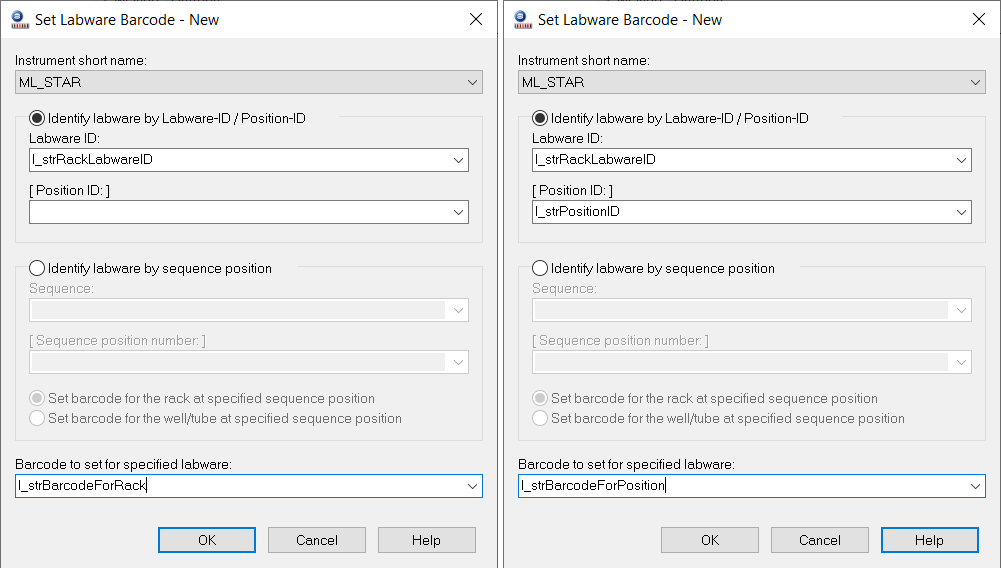

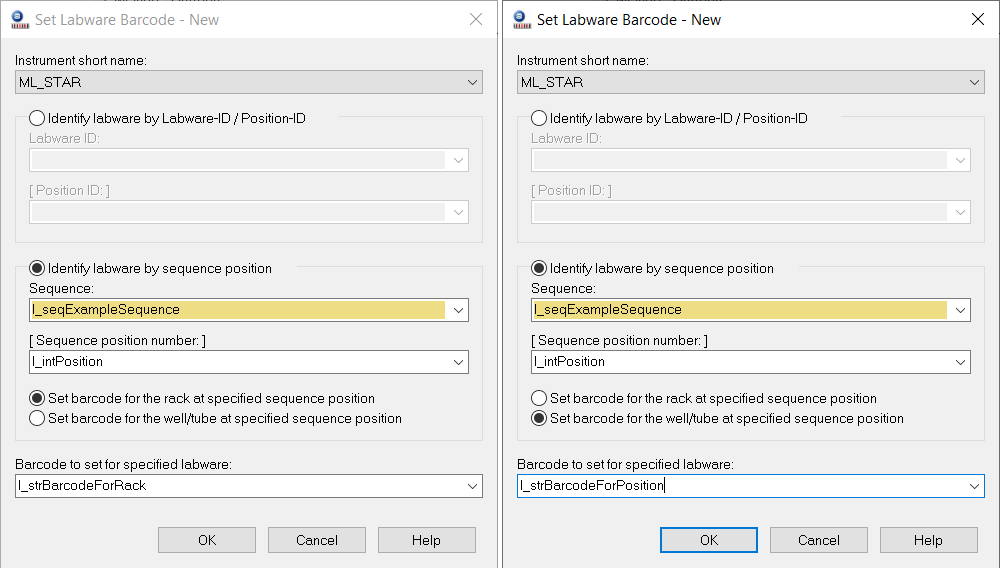

This step is my preference as it can be parameterized to set barcodes by either labware and position ID data, or by sequence position. It also allows for barcode assignment of data to both rack and position/container labware levels. Once barcode data is applied using the step, it will overwrite whatever barcode data is currently assigned to the rack or container of interest, and update the sample tracking database.

See below examples of how the step can be parameterized by both labware and sequence data, and for rack and position labware levels:

Assign barcode by labware data (rack ex on LHS, position ex on RHS):

Assign barcode by sequence position (rack ex on LHS, position ex on RHS):

Note that racks typically have numerous child containers/positions, so it is only necessary to define the rack barcode once. If the rack barcode is assigned again for a different position within the same rack, the rack barcode will be overwritten.

Hope this helps. Thanks.

-Nick