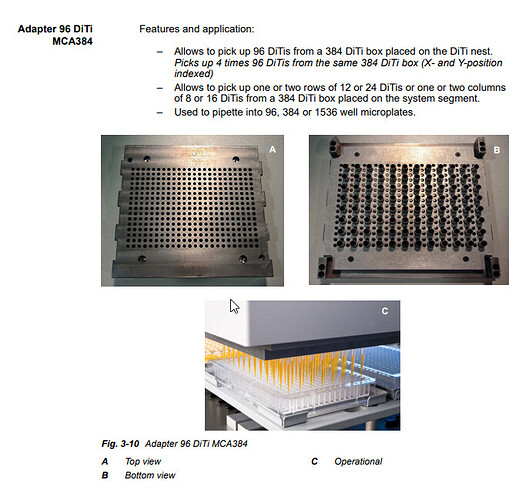

Does anybody here have experience with using the MCA adapter that allows you to pick up 96 tips from a 384 tip box?

I think it is a very useful, but we see a high error rate where it is unable to pickup tips. I was wondering if anybody managed to get it working robustly.

Yes, I recently moved an entire 384-well setup from another Tecan system onto my own. This included removing the front facia and plugging in an active diti nest control cable to port number J48 on the front computer board. The “96 MCA 384 tips” head, along with the “MCA384 Combo” is VERY finicky. I had to play with the Active Diti Nest site definitions, notably the X-offset and Y-offset, to get it to pickup tips. If the MCA sees any reverse force at a Z-height greater than (further above) the worktable then expected, it will not pickup tips. I found it helpful to make slow-motion videos on my phone to estimate what values I needed to adjust to get it perfectly above the tips for pickup. Note, some dimensions needed to be adjusted 0.05mm. That’s right, 1 20th of a mm!

Be sure to make a protocol to pickup/drop tips in all 4 quandrants using that head, as adjusting these offsets need to be appropriate for all 4 quandrants.

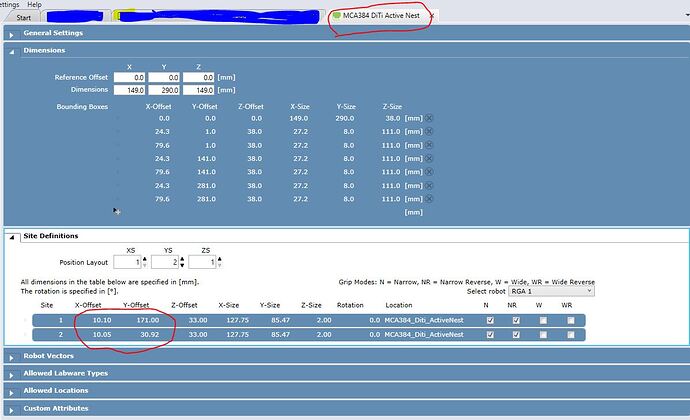

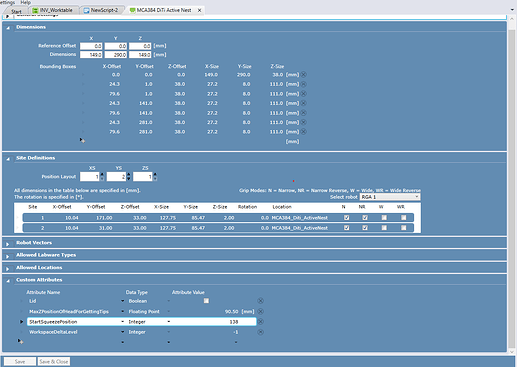

Make adjustments with the values circled in red below to line-up the head with the tip connection points as best as possible.

Yeah I got it working fairly reliably but it required a bit of trial & error with Tecan.

I think their internal wiki uses my pictures/data.

Which active nest are you using? They tend to have a few versions of it out in the field.

We have an older model Active Nest. It is the 2 position Active Nest with a Passive 41mm nest in towards the front of the instrument. This is neither the “rear” nor “front” nest, which both are a newer model that opens up additional space on the deck segment. Our active nest is roughly in the middle of the deck segment.

Let’s think about this, the Active Nest is a piece of metal that is very precisely machined. The tolerances are generally within an exact specification so the X/Y of the actual nest should not theoretically change too much. Instead I’ve found that the true variance happens at the carrier level (the deck) so I always encouraged my teammates to teach at carrier site. If your first and second Active Nest have different X/Y offsets (not relationally proportional to each other) you could be setting yourself up for failure in a high throughout environment. With that said, we do teach the Active Nest in emergency scenarios where we can’t get someone onsite to run a battery of tests…

In my experience, you have a tolerance window of 0.2 mm to get good tip mounts.

Let me repeat, assume you only have 0.2 mm’s of tolerance to get consistent tip mounts for > a few months. With that said, here’s a high level overview…

- Verify that the locator grids are in good shape and aligned with each other

- Verify that front to back movement of the arm is aligned (meaning to no visible X/Y deviation as you move across the deck)

- Verify that the MCA head is aligned (no twist, no tilt)

- Verify that the Active Nest is flush from end to end (meaning it’s consistently the same distance from the edge of the carrier and remember that even a 0.2mm deviation could spell inconsistency)

- Verify that the metal clamping mechanism is in good shape and making string clamping contact

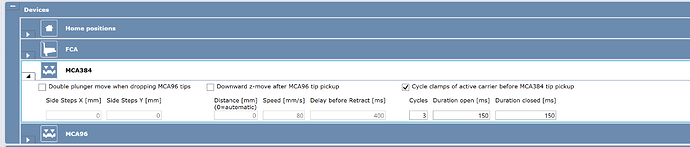

- ALWAYS triple clamp the tip box before mounting to remove any static forces in the tip box (you can now set this in config)

- Verify the adapter is in good shape, tips come off cleanly and the tip mount sound is consistent (they have an internal oil coating that needs to be replaced with time.)

- Verify that the deck segment isn’t bent out of shape (happened to me only once)

- If your active nest extends over the back segments, verify that those are flush with the rest of the actual deck.

- Verify that the system is level. Get some bubble levels and start looking around to see if you’re accidentally introducing a tilt to the whole deck somewhere.

- Verify that you are on a newer version of Fluent Control. Older versions do not have all of the wisdom Tecan acquired from it’s earliest adopters.

- Try different lots of tips. NEVER underestimate the damage a bad lot of tips can have on a system.

- Temperature & Humidity MATTER A LOT. If you are not properly regulating the temp & humidity of your lab environment, you should at least be monitoring them. I was able to correlate poor tip mounting with specific conditions in our lab and I was able to justify doing nothing about a problem that only happened because our leadership didn’t think it should be an issue… Well the data spoke!

Hopefully this helps!

With all of this said, the MCA 96-384 is an AMAZING tool but the MCA96 is pretty damn cool too and it has a variety of new bells & whistles.

This discussion makes me love my Bravos even more. ![]()

Does the Bravo have the ability to pickup 96 from a 384 tip box?

Yes, for the 96ST head it’s actually the only option. They don’t sell tips for that head in a 96-well format. The 96ST head uses the same barrels as the 384ST. But it’s nice (and this would be the same for any system with that capability) because you can give the instrument 4 tip box in one.

I will also mention that we occasionally have issues with it picking up tips but generally the opposite problem (from what was described above) will happen. If the head isn’t aligned perfectly when mounting tips the entire tip box will be picked up and travel along with the head. This is almost always due to a teachpoint issue that is easily solved, but can also happen because a tip did not get shucked off the head in a previous dispense, or a tip box wasn’t placed correctly on the plate pad.

Good to know, I guess I’ve only seen the other format.

Hi guys,

thank you very much for the input. This is very helpful ![]()

Cheers,

Ben

Can you specify the Triple clamp, never heard of that before? Also, I learned using the FCA with the move tool, and tracking the Z-coordinates, can tell you how “flush” a system is (MCA/deck). I mounted a tip on the FCA, used the move tool and physically placed it on 8 locations where a microplate would sit, then back deduced how flat a location was.

This is traversing far from the original topic and could be a new thread. Just a lil’ trick I thought of while sitting next to my 1080 bottle-fed beast.

If the tip box is physically picked up, I would check with TECAN, that could be a misaligned barrel in the head, forcing a tip to be somewhat sides. A perfect Z-drop and Z-exit should occur if the head it correctly aligned. If you are re-using tips, that could be problematic as well.

If you have an Active DiTi Nest for mounting 384 tips, this will clamp the box a variable number of times. By clamping the tip box before you tip mount, you hopefully dissipate any static forces present within the tips that may impede a proper mount.

Hello everyone,

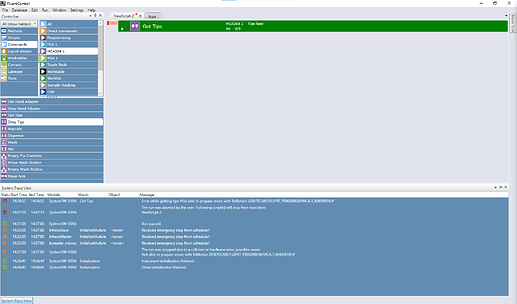

I’m reviving this thread because I’ve run into issues with the active DiTi nest.

It seemed to happen overnight.

When picking up tips, the MCA crashes on the Z-axis. It’s not because the head is too low, but because the clamps are squeezing too much.

Here’s a screenshot of the error.

This is pretty annoying because when it crashes in this position, the clamps are in the “up” position, so I have to open the clamps manually to unstick the head from the active nest.

A weird behavior: after the crash, the tips are actually in the head, so if I run another Get Tips command, it does not crash. It’s as if, when the head has no tips, it squeezes too much because it doesn’t detect them.

Here is my carrier definition :

I tried a few things:

- Moving the site up

- Adjusting the

StartSqueezePositioncustom attribute (both up and down) - Adjusting the

MaxZPositionOfHeadForGettingTipscustom attribute (up and down) - Moving the deck segment below the nest up

Now I’m stuck.

If anyone has ideas, I’m all ears. Thanks for your help!

I never had to modify any of those variables.

I provided a check list above but in my experience, the s-motor would go bad, the solenoid lost some of it’s give, the prongs attached to the solenoid in the active nest were slightly more bent than usual forcing the tip box to not be in a true A1 position, the locator grids broke, the tip box had a curvature on the bottom, static, humidity, triple clamping before mounting, and also the adapters lost their grease so you had to swap them.

If this was recently serviced, your X & Y may need to be adjusted for the deck segment as well.

Hello,

Thank you for your reply.

There has been a few development since then.

I am using the 96MCA head adapter with the 15uL filtered DiTis.

If I take a new box of 384 tips, the head does not crash. However, if I remove a couple of quadrant (let’s say A1 and A2), and I try to take tips in B1, now the head crashes.

I also noticed that if I take tips that have been used a few times, the head crashes as well.

It’s as if the head is not receiving the feedback when having the tips and keeps going down, which induces the crash.

I think I will have to call a Tecan technician and hope this can be tuned via Fluent SetUp…

Hey, I have news !

So I had to call a technician…

It was not a hardware issue and we still don’t know what happened but we upgraded the firmware and the software (from 2.3 to 3.2… I guess they didn’t have a more recent version available) which solved the problem.

So there you go ! If someone ever face the same issue, you may want to upgrade.

(Took 4 months though…)

Cheers !

yeah, that’s typical Adapter 96 DiTi MCA384 firmware behavior. when the head is empty, the clamp feedback window is off, thus it continues squeezing and forces Z into the nest. that’s why fresh boxes function, but missing quadrants or repeated tips crash it - different compliance, same poor reasoning.

If the firmware is incorrect, adjusting StartSqueezePosition won’t resolve the issue. we’ve observed this on Fluent + active DiTi nests more than once. update FW/software and it simply stops occurring. hardware’s typically good.