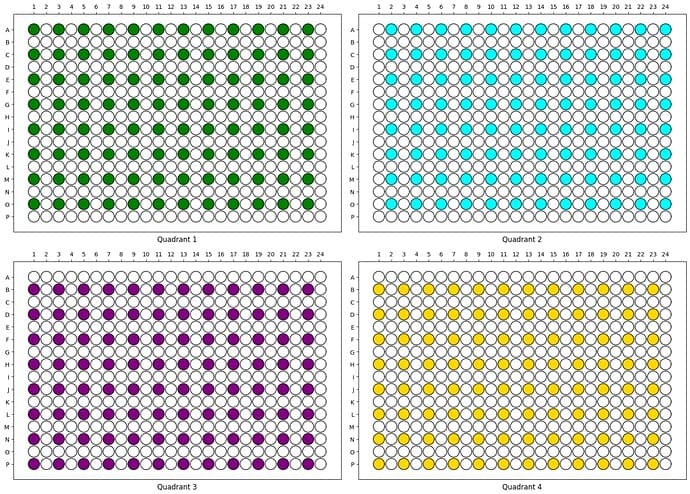

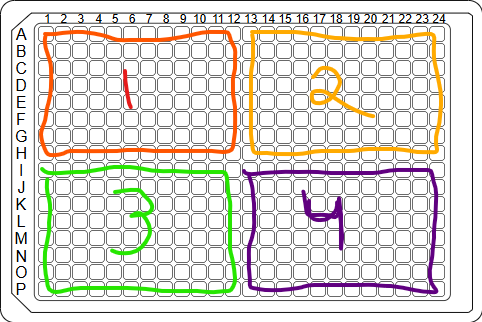

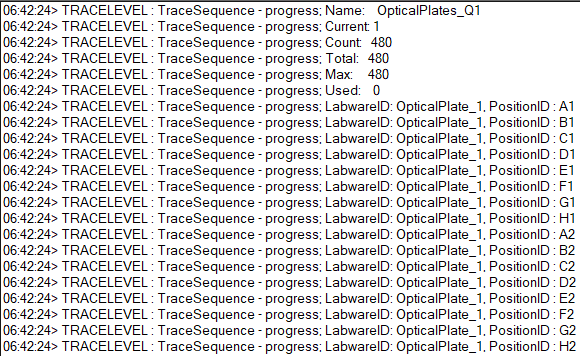

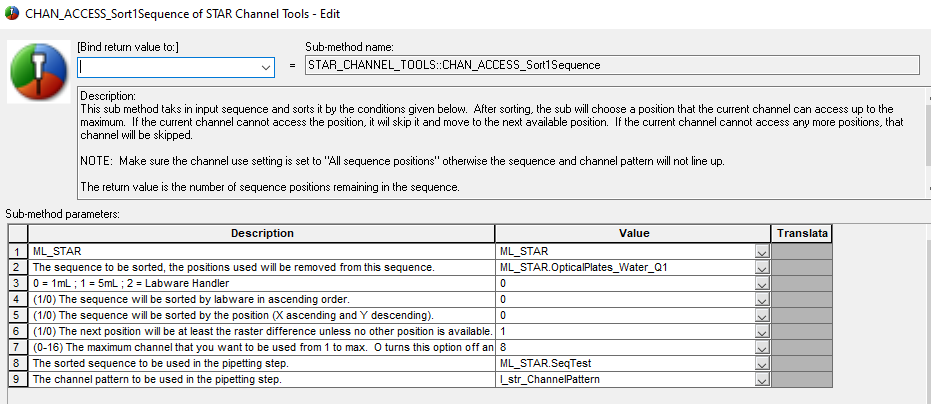

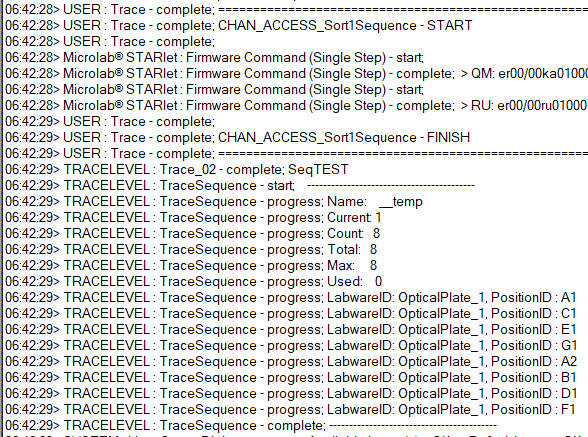

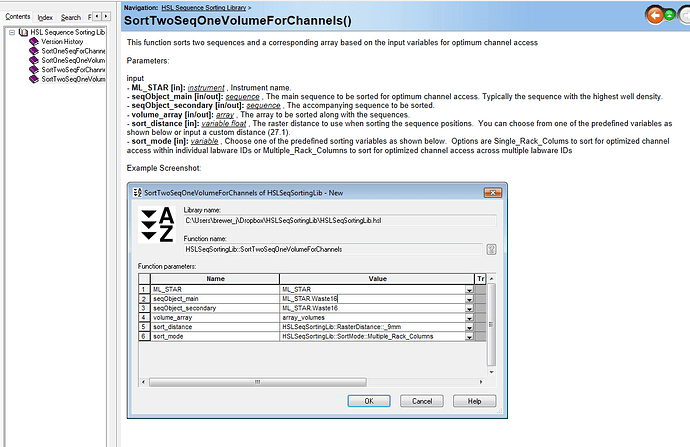

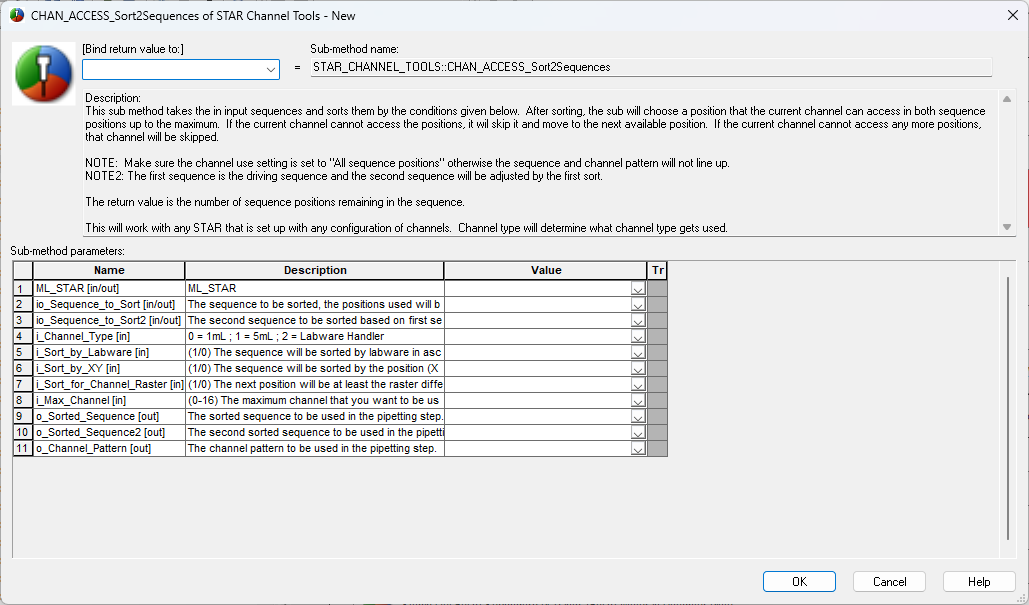

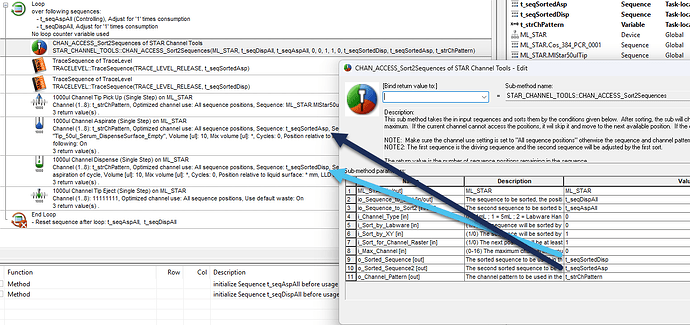

I’m writing a method that transfers volumes from a 96-well plate to a 384-well microplate using 8 1000uL channels. I have my microplate split into 4 quandrants of 96-wells for generating replicates. So A1,B1,… , G1, H1 will end up in the microplate positions of the same position. When this method is run our STARlet is able to draw up all 8 volumes from the 96-well plates, but when it dispenses into the microtiter plate because of the well spacing, it will individually pipet each target well one at a time shifting the channels between transfers. It’s much more efficient to pick up every other sample from the 96-well plate (A1, C1, E1, F1, B1, D1, G1, H1) and then dispense them in the same wells of the 394-well plate, so that 4 channels can be operating at a time. My method supports up to 480 samples at a time, and I’m adjusting the end position of my target sequence to match the number of samples so I don’t think I can preserve this dynamic sample sequence if I program the target sequence skipping every other well.

My question is what ways can I adjust the sequence to stagger the channels and sequence positions in order to be able to transfer more samples at a time? Has anyone else had to deal with a similar issue?