Is it possible to have a different grasp vector for pick up and drop off in a labware? Basically I want to pick up a plate from a position and then drop it back in the same position from a different height than I picked it up from.

Have you tried implementing a single vector for the return with the RGA?

We have something similar for our Tecan. Specific spot - down holder - is higher than all the other ones. Plate is then moved by the single vector at a specific time. After that the labware is ‘moved’ by removing from the worktable and returning on the new position on worktable. Then script continues as normal. For the pick-up from the ‘down holder’ position it does the same, but then in reverse.

I can have a look at the specifics in the script on how we implemented it, but I’m not at my work laptop at the moment. Let me know if you need to know more.

If you could send the specifics of the implementation that would be awesome!

Although not ideal, I program my instrument in a similar way. I have different nest locations programmed in the software, meanwhile the actions are physically occurring on the same nest site on the worktable.

I do a similar thing with different Compartment #s when working with tubes, as sometimes I want a very high height for “Dispense” as opposed to a low dispense height. I find different compartment #s is easier to change on-the-fly instead of delving deep into each liquid class for customization.

@Liam7b, interesting idea I would assume you guys have a relatively easy to follow naming convention for that then.

@hawk4151 original locations get the original nest value. That is, if a deck segment has 6 nests, the true nests are labeled 1-6. As they get closer to the ceiling (of the enclosure cabinet), the nest values increase by value, thus 7-12, etc. Different naming schemes would certainly be possible. 1, 1a, 1b, etc.

i had a similar need for a complex, zero-space worktable and found the best method to handle this was to utilize “execute single vector” for each command,

And define specific variables to handle the Z offset when picking up & dropping,

the use case here was to overcome complexity of the "labware offsets’, plus the variability of the application where filter plates were stacked on top of drip plates/collection plates on the deck, in a storage hotel & in a centrifuge

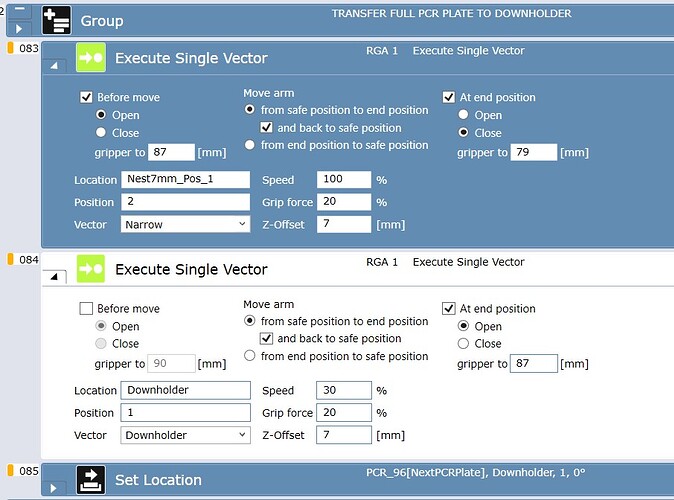

attached is the part of the script to transfer the plate from the worktable to our downholder. A PCR plate can only be added there by sliding it in from the right into the downholder position where it is a secured at one end so that we can pierce a seal without coming back up when moving the AirFCA DiTis out of the plate again.

[083] movement to open the RGA and grap the plate

[084] movement to transfer the plate to the downholder position (with a 7mm Z-Offset as the position is higher then the worktable)

[085] set the new position of the plate as this is not done when transferring a plate with a single vector.

Hope this is helpful.

That was really helpful, I get an error though saying that I haven’t picked up a plate from position even though I have, how do you get around that issue?

Make adjustments to the “Gripper to” value and/or grip force percentage.

I generally keep my speed % around 50 and force % around 30-40.

@luisvillaautomata I’ve tried a range of values for those values, but I am still getting the same issue, “Object was not gripped on source location”

Interesting, are you gripping at the bottom or on a lip? I find that sometimes that causes issues for me.

I was gripping on a skirt at the bottom of our plate, when I started gripping from above the skirt the errors stopped. Thanks for the help!